what is a process calibrator used for?

Understanding the Role and Importance of a Process Calibrator

In the world of industrial automation and instrumentation, ensuring that various systems and instruments operate correctly and efficiently is paramount. One critical tool that aids in this process is the process calibrator. But what exactly is a process calibrator, and why is it so vital in different industries? This article delves into the functionality, types, and significance of process calibrators in maintaining optimal system performance.

What is a Process Calibrator?

A process calibrator is a sophisticated device used to test, diagnose, and calibrate various instrumentation and control systems. These devices simulate different signals such as voltage, current, resistance, temperature, and frequency, allowing technicians to verify the accuracy and performance of other instruments and control systems. Essentially, process calibrators ensure that instruments provide precise readings, which is crucial for maintaining process efficiency and safety.

Types of Process Calibrators

Process calibrators come in several types, each designed for specific applications and measurement parameters. The main categories include:

- Temperature Calibrators: These calibrators simulate temperature readings for devices like thermocouples and RTDs (Resistance Temperature Detectors). They help ensure that temperature sensors and controllers provide accurate measurements.

- Pressure Calibrators: These devices are used to measure and calibrate pressure sensors and transmitters. Pressure calibrators are essential in industries where precise pressure measurements are crucial, such as in chemical processing and oil and gas industries.

- Electrical Calibrators: These are versatile devices capable of simulating and measuring electrical signals like voltage, current, and resistance. Electrical calibrators are widely used across various industries to maintain the accuracy of electrical instruments and control systems.

- Multifunction Calibrators: As the name suggests, these calibrators can handle multiple types of signals, making them highly versatile. They combine the functions of temperature, pressure, and electrical calibrators into one device, making them ideal for applications requiring the calibration of various instruments.

Why Are Process Calibrators Important?

1. Accuracy and Reliability

The primary purpose of a process calibrator is to ensure the accuracy and reliability of measurement instruments. Accurate readings are crucial in maintaining the quality and safety of processes in various industries. For instance, in the pharmaceutical industry, precise measurements are necessary to ensure the correct formulation of drugs.

2. Compliance with Standards

Many industries are governed by strict regulations and standards that mandate regular calibration of instruments. Using process calibrators helps companies comply with these standards, avoiding potential legal and financial repercussions.

3. Preventive Maintenance

Regular calibration using process calibrators is a form of preventive maintenance. It helps identify and rectify potential issues before they lead to significant problems, thus reducing downtime and maintenance costs.

4. Enhanced Safety

In industries like oil and gas, chemical processing, and nuclear power, the accuracy of measurement instruments directly impacts safety. Process calibrators ensure that these instruments function correctly, thereby enhancing overall safety.

Applications of Process Calibrators

Process calibrators find applications in a wide range of industries, including:

- Manufacturing: Ensuring that machinery and production lines operate efficiently and produce high-quality products.

- Oil and Gas: Monitoring and controlling various parameters like pressure and temperature to ensure safe and efficient operations.

- Pharmaceuticals: Ensuring accurate measurements in drug formulation and production processes.

- Power Generation: Maintaining the accuracy of instruments used in power plants to ensure efficient and safe energy production.

Popular Products

Here are some of the most popular process calibrator products:

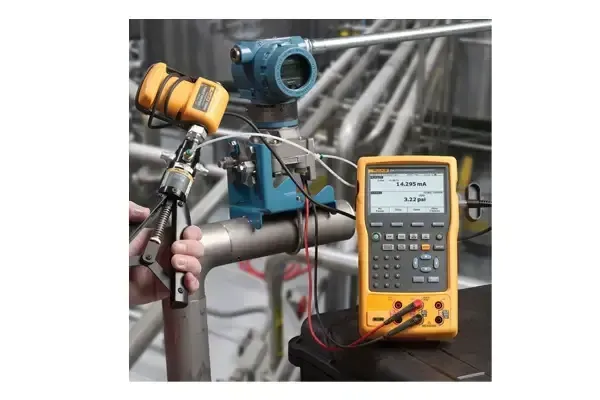

1. Fluke 754 Documenting Process Calibrator

The Fluke 754 is a multifunctional process calibrator known for its robust features and ease of use. It can document the results, making it ideal for regulatory compliance. Key features include:

- Ability to source, simulate, and measure pressure, temperature, and electrical signals

- Automated procedures and HART communication capabilities

- Large memory for storing calibration results

2. Fluke 725 Multifunction Process Calibrator

The Fluke 725 is a versatile and reliable multifunction process calibrator that is widely used across various industries. Known for its durability and ease of use, the Fluke 725 offers a range of features that make it ideal for both field and bench calibration. Key features include:

- Multifunctional Capabilities

- User-Friendly Interface

- Robust Design

- High Accuracy

- Documentation and Data Logging

3. Additel ADT227Ex Documenting Multifunction Process Calibrator

The Additel ADT227Ex is a sophisticated documenting multifunction process calibrator designed for use in hazardous environments.Key features include:

- Multifunctional Capabilities: The ADT227Ex can source and measure electrical signals, pressure, temperature, and frequency, providing comprehensive calibration solutions.

- Intrinsically Safe: Certified for use in hazardous environments, ensuring safety in potentially explosive atmospheres.

- High Accuracy: Delivers precise measurements, essential for maintaining the accuracy and reliability of critical instrumentation.